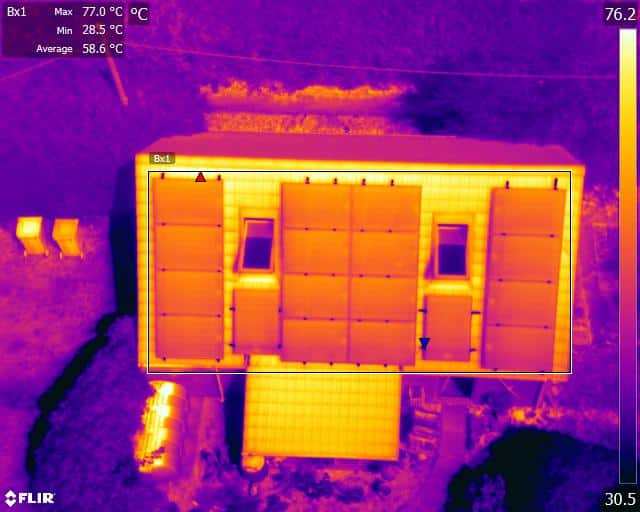

Drone Thermography to Inspect Domestic Solar Panels

Using Drone Thermography to Inspect your Domestic Solar Panels

Domestic solar panels are now a familiar sight on the rooftops of the UK, but many people fail to carry out the necessary maintenance to make sure that they are getting the most from their investment.

Faults in your panel, either caused during the installation process or occurring over time, can not only mean that your panel’s productivity falls. It can also cause a fire risk and so many companies recommend a biennial inspection to ensure safety as well as optimal performance.

Of course, the vast majority of solar panels are installed on sloping roofs which can make a manual inspection difficult and invasive scaffolding or a cherry picker may be required and there is always a risk of damage to the roof itself during the inspection process. So, it’s not surprising that many people put off the cost and inconvenience of an inspection if there no visible issues. However, drone thermography can complete a detailed panel inspection quickly, simply and cheaply with maintenance teams only then being required if a fault is found. One simply flight every two years under the right conditions can be all that it takes to make sure that your solar panels stay safe and efficient. With many panels being covered by a long term warrant, there’s a good chance that fault repairs will be at no cost to the panel owner as well!

Drone Thermography of your solar panel can detect

- Faulty cells

- PID faults

- String errors

- Defective Diodes

All of these can be visualised without ever touching the panels or roof structure – making it the perfect routine inspection tool. Drones can also be a fast and efficient diagnostic tool to pinpoint faults when production has dipped to be able give to your panel maintenance provider.

Drone Media Imaging can fly a state of the art thermal imaging camera on one of our top of the range UAVs for a very competitive rate, wherever you are in the UK. We are also qualified thermographers which means that we also understand the correct flight conditions necessary to create meaningful and accurate data and provide you with a detailed inspection report. Just get in touch to discuss your requirements.

Expert Infrared Inspections for Accurate Thermal Assessments

Need professional thermographic analysis for your project? Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.

related posts

As winter's chill recedes, the optimal period for building thermography is ending. This technology relies on temperature differences to detect energy inefficiencies. With spring's arrival, these disparities diminish, making it harder to identify problem areas. Act now to ensure your building's energy efficiency before the seasonal window closes.

Thermography, a non-invasive technique using infrared imaging, has emerged as a powerful tool in the building industry. It is particularly useful for investigating building air pressure, air flow, and inefficient air leaks. This article explores the application of thermography in these areas, providing valuable insights and practical examples.