Does Your Solar Installation Have a String Fault?

How Does Thermography Detect a String Fault?

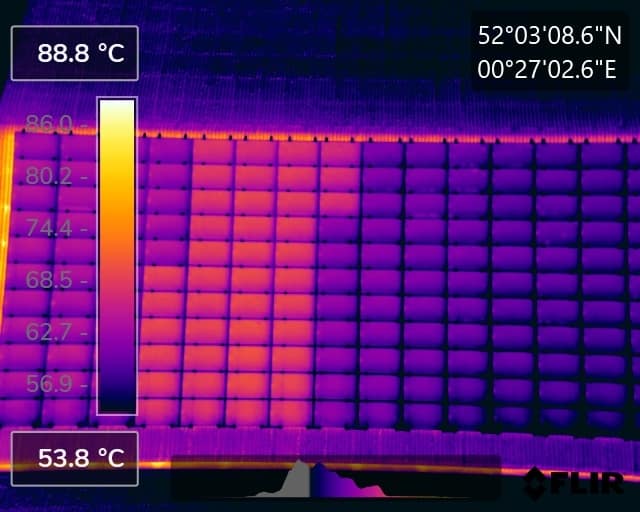

If a fault develops in solar panels connected in series, then the entire string is likely to fail or be shut down. This results in a heat differential to the surrounding panels/arrays and will show up clearly in a thermogram image. This is because when light is falling on the panel cells, but no load is connected, there is an electrical potential across it, but as no electrons are flowing (under load) then the by product is heat. As soon as something completes the circuit, electrons will flow, and the heat is distributed and equalised across the open circuit.

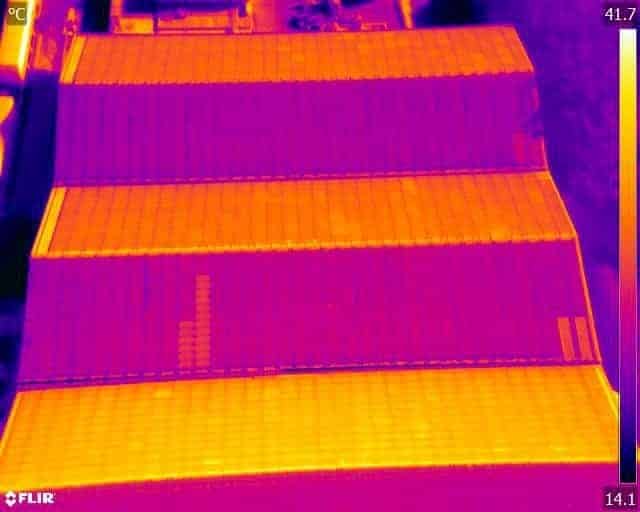

There is no turning off of a solar cell! When bright sunlight is hitting the cell surface, the energy created must end up somewhere, it will become DC electricity or heat. This can be clearly seen in the thermogram opposite, where two strings of solar panels are ‘off. but producing heat and showing up in the image.

There are of course several reasons why the sting arrays may have turned off or failed, DC Ground Faults may be one or it could be something else as a failing MCB component. However, two things are for sure, firstly the asset is not generating energy and secondly, a safety issue has or is developing. In both cases, without an inspection the issue may go unnoticed.

DC ground faults are the most common type of fault in PV systems and half go undetected.

DC ground faults are a common type of fault in PV systems and many can go undetected.

DC ground faults are a common type of fault in PV systems, and many can go undetected. Ground faults if not corrected in a solar array can cause significant safety issues such as arcs and in high voltage systems arc flashing that could lead to fire. A ground fault can be described as an unintentional electrical connection or short circuit involving ground and one or more normally designated current-carrying conductors and are surprisingly common in a photovoltaic solar installation. The electrical current does not flow to the convertor as designed but instead finds its way to the ground terminal. Inverters that detect this fault will shut down for safety, resulting in loss of solar energy production.

Solar photovoltaic installations are investment assets that are subject to wear and problems can develop overtime, which is why it is critical for regular and scheduled maintenance inspections. The cost for ground-based inspections can be high given the time it can take to cover a large MW farm, and the difficulties encountered when working at hight for roof top installations will also present challenges in time and cost.

The use of a drone fitted with a thermal camera can detect many solar panel faults in a very quick and efficient manner. Observation at height can review many acres of solar panels when it would have taken days be hand on the ground. The need for scaffolding or ‘cherry-pickers’ to access hard to reach roof installations is also irradicated.

Therefore, solar inspections by drones with thermal payloads and pilots trained in thermography techniques are the inspection method of choice. Drone Media Imaging provides simple and quick solar panel inspections by drone, and as certified level 2 thermographers can provide you with a system report showing any faults that may be present in your system.

Solar Panel Inspections

We are certified level 2 thermographers and approved drone pilots with enhanced operating permissions from the CAA. We can provide solar panel inspection services throughout the UK for both large solar farm and commercial installations as well as smaller domestic installations.