Common Causes of Solar System Under Performance

Not All Solar Panel Issues are Electrical Cell or String Faults

Extensive Panel Shadowing

Shattered / Broken Glass Covering

Dirt on the Panels

One very common cause of panels not functioning effectively is simply that they have become dirty over time, particularly in urban city locations, this can diminish performance by up to 10%. Regular panel cleaning can solve this problem. Check out our article on how to safely clean your solar panels here. However, if your panels have been on the receiving end of lichen growth or bird droppings, it is possible that hot spot damage has been caused that cleaning off the surface won’t fix. So, once you have cleaned your panels, you might still see that they are not operating at an optimum level.

Shadowing / Shaded Panels

It might be that your solar panels are being partially shaded. For example, by trees that have grown since installation. Whilst this won’t damage your panels, it will be worth clearing any overgrown trees and large shrubs so your panels can once again enjoy a clear view of the sun.

Degradation

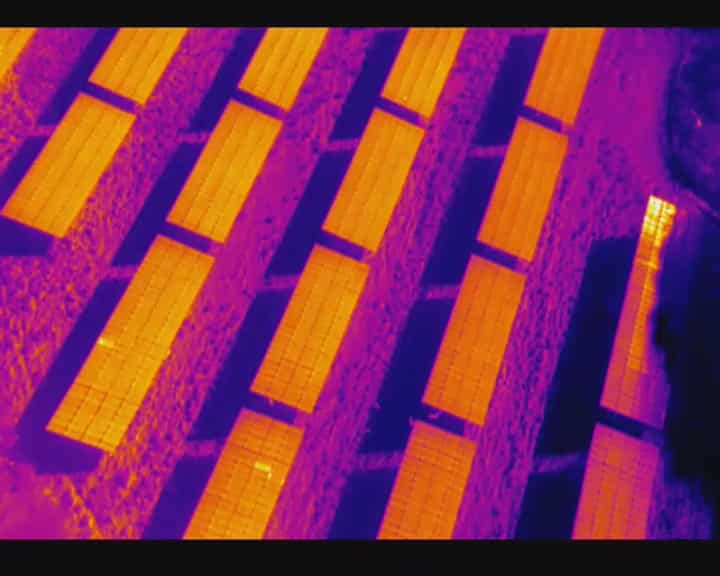

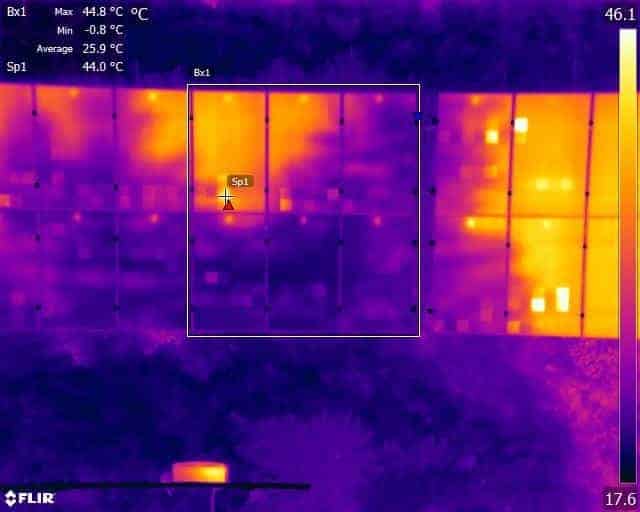

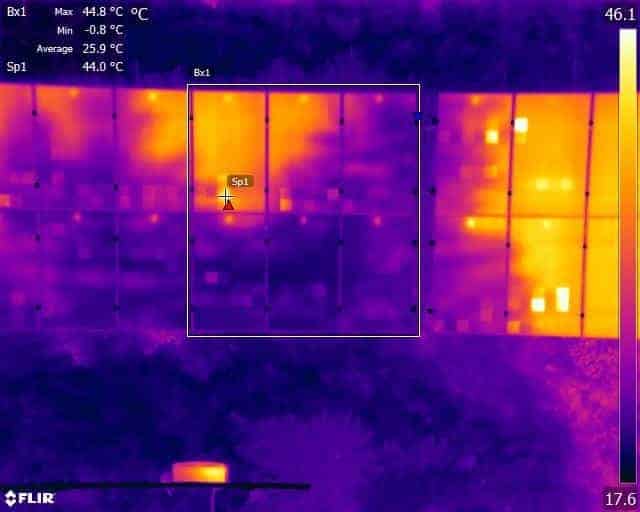

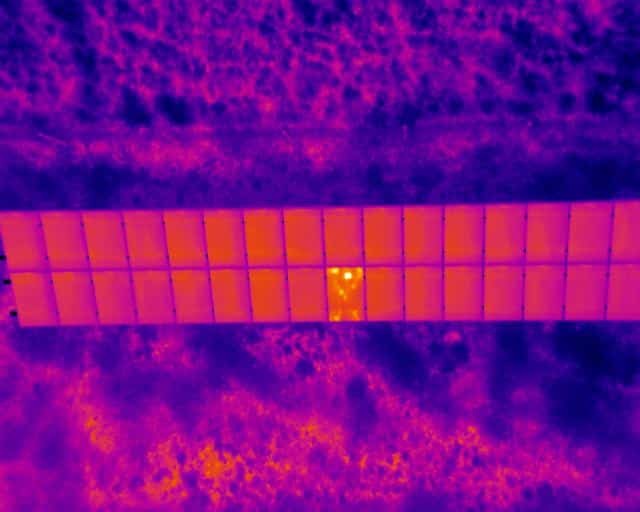

Infrared Thermal Imaging

All solar panels will suffer from degrees of degradation over time, they are not likely to function at peak capacity forever. Ironically, exposure to UV light can cause some of these degradations as it can discolour the back sheet that protects the PV cells and other electrical components. Drastic fluctuations in temperature or prolonged exposure to high heat and humidity can also cause loss of performance over time and should be reviewed as part of a regular maintenance programme.

Physical Damage to Panels

Depending on the location of your panels, they could be vulnerable to damage from debris, stones kicked up from a nearby road, falling tree branches or even heavy hailstorms. Even small twigs or acorns can cause small scratches to the panel surface that will decrease the amount of energy a panel can absorb. A smashed or cracked panel will perform less well and will become more vulnerable to water ingress over time.

Water Damage

Damaged or cracked panels are obviously more likely to suffer from water damage but seals can also fail over time and let in water. This water can damage the electrical components inside your panels and cause them to fail or at least under-perform. Where seals have failed, a professional solar panel contractor will be able to renew them for you.

Manufacturing Defects or Faulty Installation

Each panel should be tested when it leaves the factory, but it is possible that manufacturing or installation issues can occur as not all manufacturers are equal. Cheaper panels are likely to be cheap for a reason, with cheaper component parts and less quality control. We recommend an inspection after an installation to make sure that everything is functioning as it should. Catching any faults early can mean that you can have them rectified within any warranty period.

PID (Potential Induced Degradation)

Also known as a solar yield killer, is an undesirable performance deterioration induced by the negative potential to ground. It develops internally in the solar modules after a few days or weeks of installation. Poor manufacturing will cause PID to develop and can be further induced by temperature and high humidity fluctuations.

Solar Panel Thermal Inspections

We are certified and approved drone pilots and qualified level to thermographers who work throughout the UK to provide both aerial and ground based thermography services. Fully insured and certified by the CAA with enhanced OSC permissions for day and night time flights

Expert Infrared Inspections for Accurate Thermal Assessments

Need professional thermographic analysis for your project? Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.

related posts

How To Detect A Faulty Solar Panel.? When faults develop with a solar panel the result is that these cells will heat up. This is because the energy generated by the electrons moving around is not flowing through the panel and onto the convertor, and must manifest somehow, it doesn’t can’t just disappear, so the energy becomes heat.