Ensuring Energy Efficiency from Domestic Solar PV Panel Inspections

Photovoltaic Solar panels (PV) allow homeowners to generate their own electricity, reducing their reliance on traditional energy sources and lowering their utility bills. This can result in significant savings over time. with the added benefit that solar energy is a clean and renewable source of power, which helps to reduce carbon emissions and combat climate change. Solar panels require minimal maintenance and have a long lifespan, making them a cost-effective investment in the long run.

Inspecting your home solar panels each year is crucial for ensuring their optimal performance and longevity and is often a requirement of home insurance companies. Using thermal imaging is the most efficient and easy way to inspect your home solar panels for various reasons. Firstly, thermal imaging technology allows for quick and accurate detection of any potential issues or malfunctions in the panels. By detecting variations in temperature, it can identify hotspots, which could indicate faulty connections, damaged cells, or other problems that might affect the overall performance of the system. This non-contact method of inspection eliminates the need for physical access, reducing the risk of accidental damage to the panels.

Drones provide a quick and efficient method for assessing the condition of solar panels. Instead of manually inspecting each panel, which can be time-consuming and potentially dangerous, drones can cover a large area in a short span of time – minutes for a domestic roof installation. This not only saves time but also minimises the risk of accidents or injuries from working at height.

By detecting problems and anomolies early on, homeowners can address them promptly, ensuring optimal performance and maximising energy generation. Furthermore, drone inspections are cost-effective as they eliminate the need for installing scaffolding or specialised MEWPs equipment, making it an affordable option for homeowners. Overall, the use of drones in inspecting home solar panels offers convenience, safety, efficiency, and cost savings.

Fixed Price Domestic Solar Panel Inspections

Using thermal Imaging to Detect Issues with Solar Panel Installations

Why should use a qualified thermographer to inspect you solar panels?

Using a qualified thermographer to inspect your solar panels is essential for ensuring the optimal performance and longevity of your investment. A thermographer is trained and knowledgeable in the field of thermal imaging and can accurately identify any potential issues or defects in your solar panels.

By utilising their expertise, they can detect diode anomalies, cell hot spots, potential induced degregation (PID), or other hidden problems and faults that will not be visible to the naked eye. This early detection can prevent further damage, reduce the risk of system failure, and ultimately save you time and money on repairs or replacements. Additionally, a qualified thermographer will provide you with a detailed analysis and comprehensive report, outlining the current condition of your solar panels and offering recommendations for maintenance or improvements.

Overall, investing in a certified thermographer’s inspection will ensure the optimal performance and efficiency of your solar panels, maximising your return on investment and promoting a sustainable energy future.

How does thermal imaging of solar panels work and what are its benefits in assessing their performance?

Thermal imaging of solar panels is a technique used to detect and analyse the temperature distribution across solar panels. It involves the use of specialised cameras that capture infrared radiation emitted by objects. Solar panels, when operating optimally, should have a uniform temperature distribution. However, factors like faulty connections, dirt accumulation, or damaged cells can cause temperature variations, indicating potential anomalies and issues.

The infrared camera detects these temperature differences, and the captured images (thermograms) are then processed to create thermal maps of the panels. This enables solar panel thermographs to identify specific areas that require maintenance or repair, helping to maximise energy production and efficiency. Additionally, thermal imaging can also be used for preventive maintenance, as it allows early detection of potential problems before they cause significant damage.

IEC Solar Inspection Services

We are certified master thermographers, experienced in solar panel inspection to IEC standards. We can complete both the structured and compliant data capture through to the formal inspection report. As approved drone pilots we work throughout the UK to provide both aerial and ground based thermography services. Fully insured and certified by the CAA with enhanced permissions for day and night time flights.

Schedule your inspection with our expert thermographers. Maximise the efficiency and longevity of your solar system while ensuring the safety of your home. Don’t wait for unexpected issues to arise – take proactive steps to maintain your investment. Click here or contact us now to book your inspection and unlock the full potential of your solar power installation.

Domestic Solar Panel Inspection Service

The International Electrotechnical Commission (IEC) sets out specific environmental conditions that must be met when conducting a thermal solar panel inspection. These conditions ensure the accuracy and reliability of the inspection results.

- Sun Shine: > 600 wm2 of irradiation

- Low Winds: Wind speed below 12 mph

- No Panel Moisture: No rain, fog or precipitation

- Underload: The panel installation should be on and under load.

The work should be completed by a qualified and certified thermographer with a minimum level 1 categorisation.

A solar panel thermal inspection involves fly a drone with a thermal camera attached over the panels to record radimetric thermal data for later anaysis and reporting.

- Drone Flights: Planning the drone flight includes risk assessment of airspace, neighbouring properties and the distance to univolved people.

- Insurance: Commercial drone flights are subject to manditory insurance

- Time on Site: For a typical detached property with up to 20 panels, the time on site is about an hour. 20 minutes to setup and complete a site assessment, 20 minutes drone setup, calibration and flights, and 20 minutes pack away.

- Data Reporting: The thermal data collected from the drone flight is then subject o post-production, analysis and reporting, which is usually completed in 5-10 business days.

We use the latest sophisticated drone and thermal infrared camera equipment to complete the inspection, coupled with our many years of exstensive thermographic experience.

- DJI M210 Drone: The DJI M210 is a highly advanced drone that offers exceptional performance and versatility. It is designed for professional use and comes with a range of impressive specifications. The M210 features a dual battery system that allows for extended flight times and increased reliability.

- DJI XT2 Camera: The DJI XT2 Camera is a highly advanced and powerful imaging solution designed specifically for industrial applications. It features a dual-sensor setup, combining a high-resolution 612×540 30hz radiometric thermal sensor with a 12-megapixel RGB visual camera. This combination allows users to capture incredibly detailed thermal and visual images simultaneously.

- FLIR T530 Ground Camera: The FLIR T530 thermal camera is a high-performance device that offers advanced imaging capabilities for various applications. It features a 320 x 240 infrared resolution, providing excellent image quality and clarity. With a temperature range of -20°C to 650°C, it can accurately detect and measure temperature differences.

Get a Quotation

IEC Solar Inspection Services

The price for completing an IEC 62446-3:2017 survey includes the following

- Certified Master Thermographer Level 3 – IEC Solar Panel Report

- Expense – Travel Fee

- Plus VAT

It is possible that there are no faults or anomalies found in your installation, in which case the report will confirm this finding. Thermal solar inspections will only determine faults and anomolies with the panels and not the cabling, electrical installation work, or invertors.

What is Thermography?

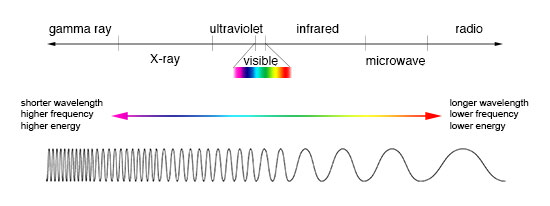

All objects with a temperature above ‘absolute zero’ (equivalent to −273.15°C on the Kelvin scale) give off infrared radiation (heat). Thermal imaging technology is designed to detect the intensity of this radiation, and after consideration of other factors, determines the objects temperature as it is emitted from its surface. A thermal imaging camera (or infrared camera) is designed to detect the radiation intensity and render the different temperature values recorded as artificial colours so that the human observer can “see visibly” the temperature differences and the overall temperature picture.

When undertaking thermal inspections, we use sophisticated thermal imaging cameras with detector/sensor sizes up to 640×480 pixels for aerial inspections by drone and 320×240 pixels for ground handheld inspections.

In digital camera terms, this may appear to be a very low resolution, but it should be noted that all thermographic sensors are small by design and that the data captured is equivalent to a thermometer in each cell/pixel; a maximum of 307,200 thermometer readings in every image for a 640×480 sensor. Alongside each thermogram we also take a normal small RGB digital photograph so the viewer is correctly orientated when looking at the Thermogram, this RGB digital photograph is of low resolution and should only be used for an overview.

The Thermographic Inspection Process

Thermal imaging is a reflective temperature technology and can only return the temperature radiated off a given surface, not specifically what is underneath or behind the surface i.e. infrared cannot see through walls or roofs, including glass. While we attempt to collect and record the data accurately, the specific values obtained should be regarded with a degree of caution and understanding. Variable environmental conditions together with changes in camera angle, subject distance, and object’s material construction, along with changes in the emissivity of the surface inspected, can all effect the results.

However, as heat permeates the substances surrounding the heat source via conduction, convection, or radiation, it therefore remains worthy of analysis and presents an opportunity to indicate several ‘out of sight’ faults or failures and thermal activities. By combining images with equal parameters within a known consistent environment, the ‘relative’ change of temperature across a selected material/subject will be accurate and therefore useful analysis can be made. The inspection and this subsequent report should be considered as a “Qualitative Evaluation” inspection and not a “Quantitative Evaluation” which would show accurate temperature values/data.

Domestic Solar Panel IEC Inspections

Quantitative and qualitative thermography are two essential methods in thermal imaging analysis. Quantitative thermography measures exact temperature values, while qualitative thermography focuses on pattern recognition. Both play a crucial role in building inspections, electrical fault detection, and industrial diagnostics. Understanding their differences helps professionals choose the right approach for accurate thermal assessments. Drone Media Imaging provides expert thermographic services, ensuring precise, reliable results. Contact us today for professional thermal imaging analysis.

The Importance of Building Thermography Surveys in the UK and the Role of Level 3 Certified Thermographers Building thermography is a non-destructive diagnostic method that uses infrared technology to detect thermal anomalies in structures. In the UK, this approach has become critical for energy efficiency, structural integrity, and safety assessments, especially with rising environmental standards and compliance requirements like BREEAM (Building Research Establishment Environmental Assessment Method. Applications of Building Thermography Energy Efficiency Audits: Identifying heat [...]