Photovoltaic Solar Panel Inspections

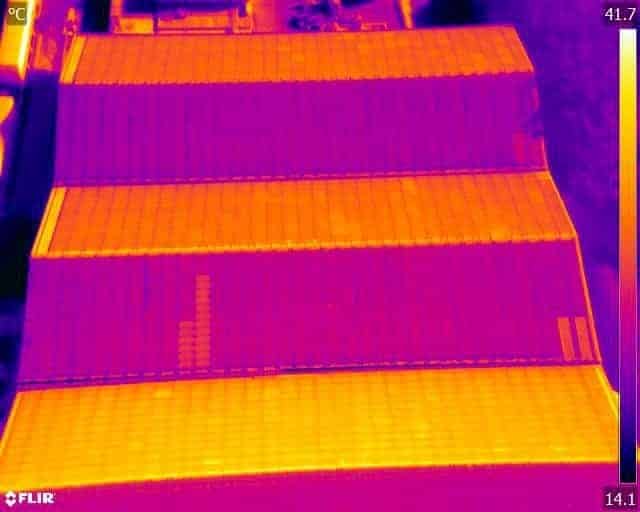

Of course, the vast majority of solar panels are installed on sloping roofs which can make manual surveys by people difficult. Invasive scaffolding or a cherry picker may be required and there is always a risk of damage to the roof itself during the inspection process.

So, it’s not surprising that many people are put off by the cost and inconvenience of domestic solar panel inspections if there are no visible faults or issues evident from the ground.

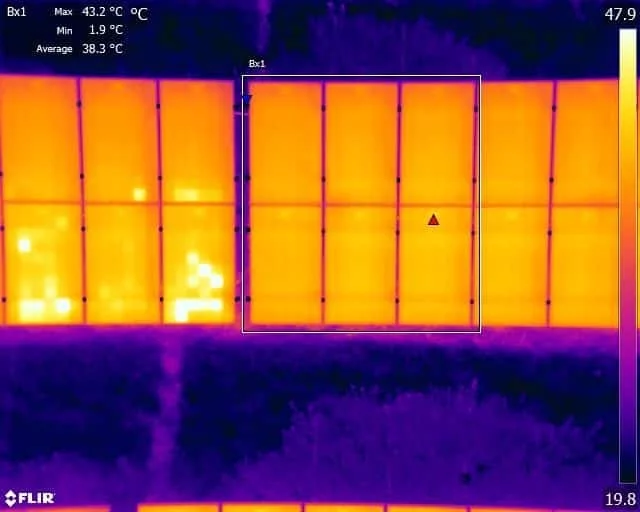

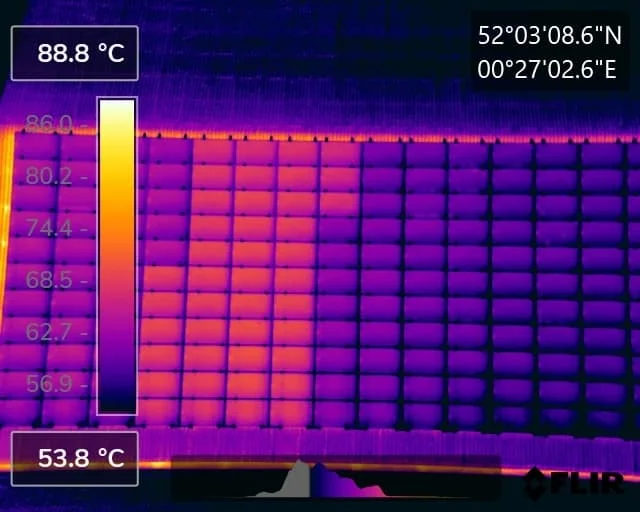

However, thermal infrared inspections using a commercial Unmanned Aerial Vehicle (UAV or Drone) can complete a detailed PV panel inspection quickly, simply, and cheaply with the need for further maintenance only then being required if a fault issue is found. One simple inspection, every couple of years under the right solar irradiation conditions can be all that it takes to make sure that your solar panels stay safe and efficient. With many panels being covered by a long term warranty, there is a good chance that any fault repairs required will be at no additional cost to the home owner as well!

Drone Thermography of your solar panel can detect

All of these issues can be visualised without ever touching the panels or roof structure – making it the perfect routine inspection tool.

A UAV/Drone can be a fast and efficient diagnostic tool to pinpoint faults when electricity production has dipped. to be able to give to your panel maintenance provider.

Drone Media Imaging can deploy a thermal imaging camera via drone at very competitive rates, wherever you are in the UK. We can operate at reduced distances to other properties and people under our OSC (Operating Safety Case) which are unique enhanced operating permissions granted to us by the CAA. We are also qualified as category 2 thermographers which means that we understand the correct thermal conditions necessary to create meaningful and accurate data, along with the correct interpretation, and can provide you with a detailed inspection report which will show you where the faults are.

Just get in touch to discuss your requirements. Get in Touch

Quantitative and qualitative thermography are two essential methods in thermal imaging analysis. Quantitative thermography measures exact temperature values, while qualitative thermography focuses on pattern recognition. Both play a crucial role in building inspections, electrical fault detection, and industrial diagnostics. Understanding their differences helps professionals choose the right approach for accurate thermal assessments. Drone Media Imaging provides expert thermographic services, ensuring precise, reliable results. Contact us today for professional thermal imaging analysis.

The Importance of Building Thermography Surveys in the UK and the Role of Level 3 Certified Thermographers Building thermography is a non-destructive diagnostic method that uses infrared technology to detect thermal anomalies in structures. In the UK, this approach has become critical for energy efficiency, structural integrity, and safety assessments, especially with rising environmental standards and compliance requirements like BREEAM (Building Research Establishment Environmental Assessment Method. Applications of Building Thermography Energy Efficiency Audits: Identifying heat [...]

10m Take off & 20m Flight

Legally, drones are required to remain a 50m distance from People, Property, Vessels, and Vehicles that are not under the control of the pilot. We, however, have enhanced permissions from the CAA that means we can get as close as 10m, reducing the need to contact and liaise with your neighbours or closing roads to fly near them.

FLIGHT TIMES ARE SHORT AND SIMPLE

Solar panels are usually fitted on one side of your house roof, looking south to ensure that the maximum solar radiation is captured efficiently. This means that the flight need is very small and simple, it is just a case of flying up above the panels to the correct angle of incidence to collect the thermal images required. Our time at your property is very short.

WEATHER REQ FOR SOLAR INSPECTIONS

Solar panels need to be operating at full load for thermal inspection to take place and all errors/faults to be clearly seen, this is equivalent to 600 watts/m2 to meet BSI standards. (400 watts/m2 can be ok for some main issues). This means that we conduct solar panel inspection in the summer months ideally usually between May and September.