When should I have my solar panels inspected?

Why is Regular Solar PV Inspection Important?

Solar panels are becoming an increasingly common sight on rooftops across the UK and there are any number of companies that can offer a quick and easy installation for you. In a matter of weeks, you can be saving money on your electricity bill!

However, once your installation is complete, it’s really important to keep on top of the inspection and maintenance routines to make sure it’s functioning both safely and efficiently. Failing Solar Photovoltaic Panels not only will lose you money and missed opportunity, it can in extreme conditions present a fire hazard – Read here about a Solar Panel fire at a Walmart Store

Drone Media Imaging solar panel service offers a hassle-free thermal inspection to check that your panels are working as they should.

Is it important to inspect Solar Panels regularly?

One of the first checks you’ll want to perform is a post installation assessment to make sure that everything has been installed correctly and that there are no errors. Carrying this out within a short time from your panels going live means that you can call your installation team to rectify any faults discovered within the warranty period. It also means that you will be saving the maximum amount on your electricity bill as soon as possible after your solar investment!

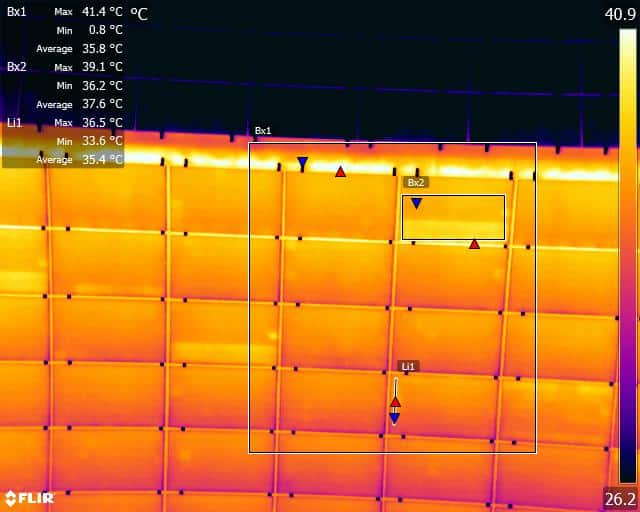

Obviously, you should order an inspection if you can see signs of damage to your panels, that’s pretty clear. However, many faults that are possible for solar panels to suffer from are invisible to the naked eye and that is where thermal images can be of great value. Using our state-of-the-art thermal camera on one of our drone fleet and, flown under the right conditions, we can quickly and easily carry out a complete system health check in a matter of minutes. Any problems are clearly highlighted on the resulting images and, if you then require corrective action, you can give those images to your maintenance company, and they can complete repairs in a targeted fashion. That means that you don’t incur the expense of having people up on your roof unless they really need to be there (and minimise chances of any damage to your roof during the process).

Where you and your neighbours all have solar panels, it can be cost effective to come together and organise your solar panel inspections. Drone Media Imaging can offer discounts where this is the case so you can all benefit from the savings.

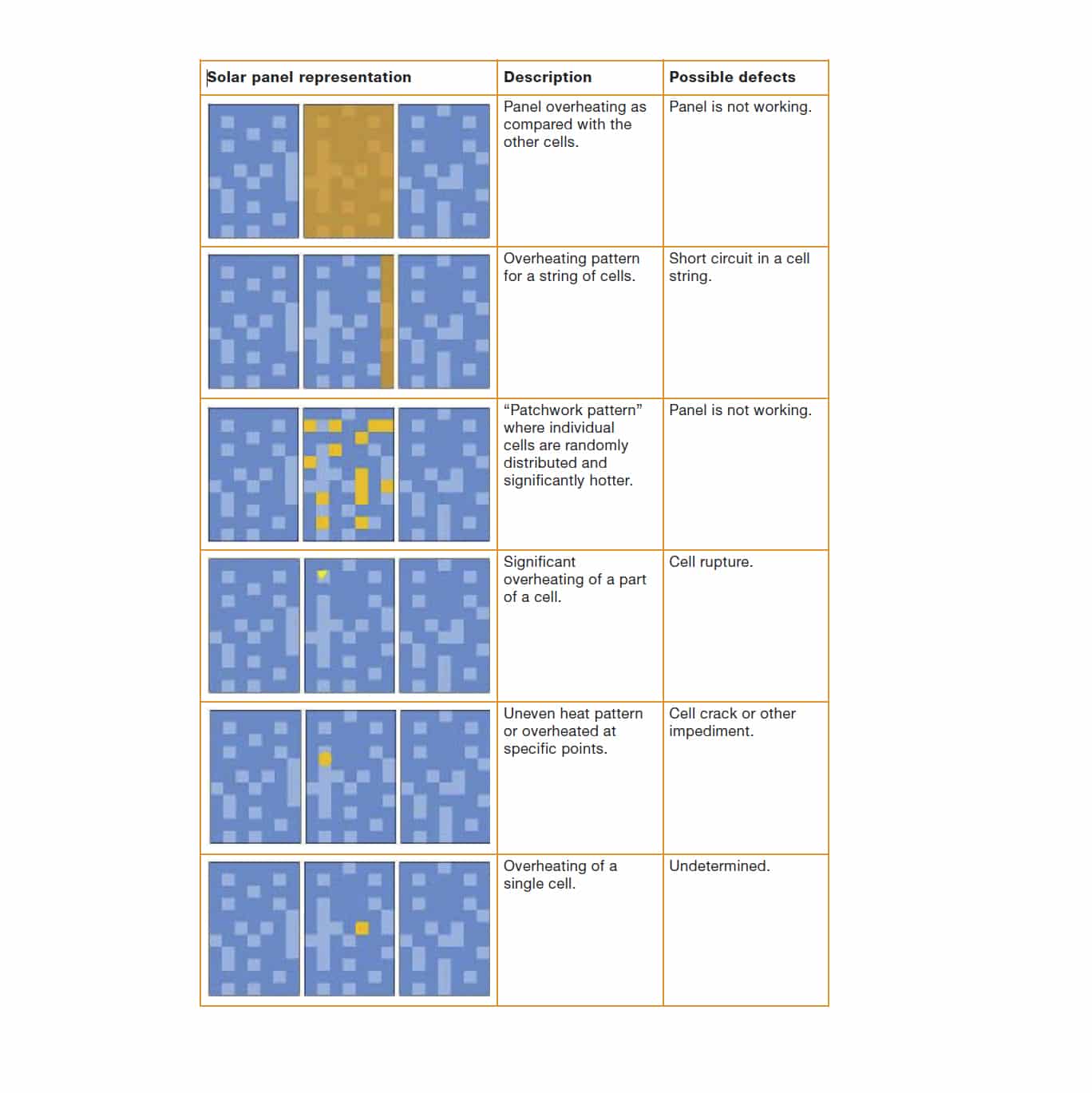

Potential Solar Panel Faults

How to Photovoltaic (PV) Panels Work?

Solar panels are made out of photovoltaic cells that convert the sun’s energy into electricity. When the sun shines onto a solar panel, energy from the sunlight is absorbed by the PV cells in the panel. This energy creates electrical charges that move in response to an internal electrical field in the cell, causing electricity to flow.

Photovoltaic cells are placed between layers of semi-conducting materials such as silicon. Each layer has different electronic properties that energise when hit by photons from sunlight, creating an electric field. This is known as the photoelectric effect – and it’s this that creates the current needed to produce electricity.

Solar panels generate a direct current (DC) of electricity. This is then passed through an inverter to convert it into an alternating current, which can be fed into the National Grid or used by the home or business the solar panels are installed on.

Utilising Drones with Thermal Cameras to Survey Solar Farms

Solar farms play a crucial role in generating clean and sustainable energy. To ensure their optimal performance, regular inspections and maintenance are essential.

Traditional methods of surveying solar photovoltaic (PV) panels can be time-consuming, costly, and require specialised equipment. However, the advent of drones equipped with thermal cameras has revolutionised this process, offering a more efficient and cost-effective solution.

Drone Media Imaging as specialist Solar Panel Thermographers, understand the key factors that impact the use of drones with thermal cameras for surveying solar farms, including cost, pricing, efficiency, speed, and the importance of considering the impact on photovoltaic panels.

Drones equipped with thermal cameras have transformed the way solar farms are surveyed, offering significant benefits in terms of cost savings, efficiency, and speed. By leveraging this technology, solar farm operators can conduct more frequent and comprehensive inspections, enabling the early detection and resolution of potential issues.

Collaborating with qualified thermographers suxh as Drone Media Imaging, enhances the accuracy and effectiveness of the survey process. It is crucial for solar farm operators to consider the impact on photovoltaic panels when deciding on the timing and frequency of surveys. While challenges and trade-offs exist, the advantages of using drones with thermal cameras ultimately outweigh the limitations, offering a powerful tool to optimize the performance and longevity of solar farms.

Cost and Money Saving Benefits

One of the primary advantages of employing drones with thermal cameras for solar farm surveys is cost savings. Traditional inspection methods often involve manual labor, extensive equipment, and significant time investment.

Drones equipped with thermal cameras streamline the process, reducing labor costs and the need for expensive specialised equipment. By automating the flights and data collection the inspection process is short and efficient, solar farm operators can save both time and money, ensuring more frequent and comprehensive surveys without incurring substantial expenses.

Efficiency and Speed

Efficiency and speed are critical factors when it comes to surveying large-scale solar farms. With drones, the entire process becomes significantly faster compared to manual inspections. Drones can cover vast areas in a fraction of the time, minimising disruption to daily operations.

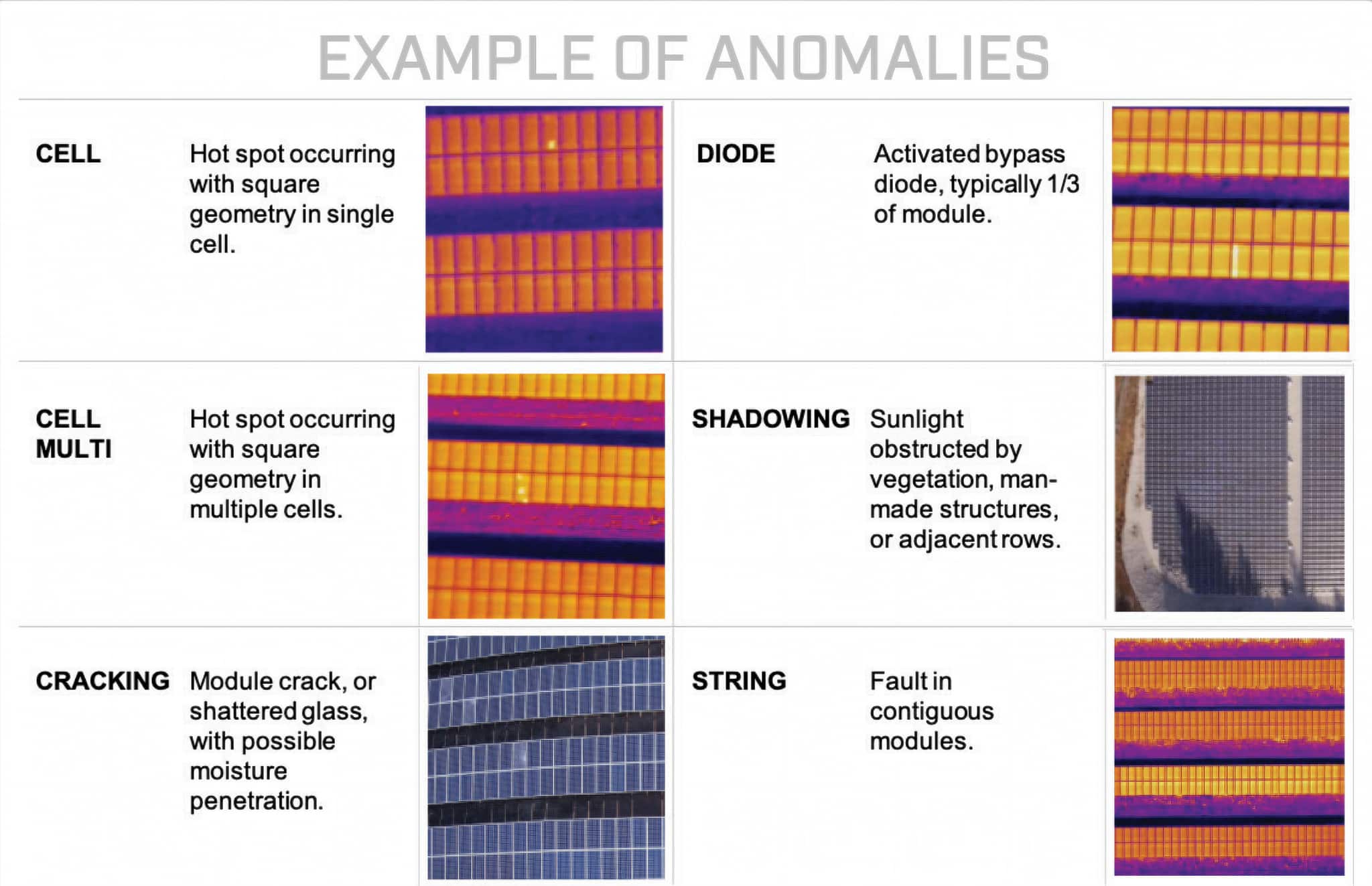

By utilising thermal cameras, these drones can capture detailed images of the solar panels, enabling the identification of potential issues, such as hotspots or malfunctioning modules, by-pass diodes and cells. The rapid turnaround time allows operators to address problems promptly, minimising energy losses and optimising overall system performance.

Qualified Thermographer Expertise

While drones with thermal cameras simplify the surveying process, the expertise of a qualified thermographer remains essential.

Interpreting thermal images and accurately identifying anomalies require specialised knowledge and training. Collaborating with a thermographer such as Drone Media Imaging, who possesses the necessary skills, certification and experience ensures that potential issues are properly detected and addressed. Their expertise can lead to more accurate analysis, allowing for timely preventive measures and reducing the risk of costly repairs or production losses

Considerations for Photovoltaic Panels

When deciding on the frequency and timing of surveys, it is crucial to consider the impact on anomalies and faults may have on the photovoltaic panels.

Continuous exposure to intense sunlight and environmental factors can cause wear and tear over time. Regular inspections with thermal cameras enable the identification of deteriorating panels, enabling proactive maintenance and replacement. By addressing potential issues promptly, solar farm operators can maintain optimal energy production levels and extend the lifespan of their PV panels.

Challenges and Trade-Offs

While drones with thermal cameras offer numerous benefits, some challenges and trade-offs need to be considered. Weather conditions can impact drone operations, as strong winds, rain, or extreme temperatures may limit flight capabilities.Thermal surveys will always require dry moisture free modules and low winds to minimise the wind chill across the panels, and of course enough sunsihine to ensure there is a minimum of 600 w/ms or irradiaiton to ensure faults show up.

Additionally, the initial investment in drones and thermal camera equipment can be significant. However, over time, the cost savings and efficiency gains provided by this technology can offset the upfront expenses.

Ease of Deployment

The ease of deploying drones equipped with thermal cameras is another advantage worth noting. Drones can be launched quickly, making them suitable for immediate inspections or responding to emerging issues. Their versatility allows for easy maneuverability and access to challenging areas, such as rooftops or other hard-to-reach locations.

The ability to deploy drones swiftly ensures efficient surveys and minimizes disruptions to the solar farm’s operations.

Solar Photovoltaic Panel Inspection Service

We are certified and approved drone pilots and work throughout the UK to provide both aerial and ground based thermography as well as, aerial photography, video/filming and photogrammetry services. Fully insured and certified by the CAA with enhanced permissions for day and night time flights

Quantitative and qualitative thermography are two essential methods in thermal imaging analysis. Quantitative thermography measures exact temperature values, while qualitative thermography focuses on pattern recognition. Both play a crucial role in building inspections, electrical fault detection, and industrial diagnostics. Understanding their differences helps professionals choose the right approach for accurate thermal assessments. Drone Media Imaging provides expert thermographic services, ensuring precise, reliable results. Contact us today for professional thermal imaging analysis.

A Level 3 Master Thermographer ensures precision, compliance, and cost savings in thermal imaging. Learn why their expertise is vital across industries like energy, construction, and manufacturing, and discover the tangible benefits of hiring a true professional in thermography.