How Thermography Enhances Building Surveys

Unveiling Hidden Issues: How Thermography Enhances Building Surveys

Building surveys play a crucial role in assessing the condition of a property, identifying potential issues, and ensuring the safety of its occupants.

However, traditional survey methods often fall short in detecting hidden problems that can have serious consequences if left unaddressed. This is where thermography, a non-invasive and highly effective technology, comes into play. Drone Media Imaging utilise the power of thermography and how it enhances building surveys by uncovering hidden issues that may otherwise go unnoticed.

The Power of Thermography: How this Technology Enhances Building Surveys

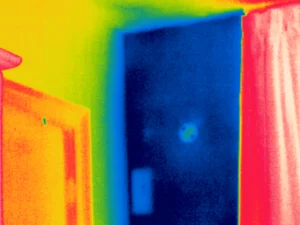

Thermography, also known as infrared imaging, utilises thermal cameras to capture and analyse the heat patterns emitted by objects and surfaces. This technology enables surveyors to identify anomalies in temperature distribution, which can indicate underlying issues such as insulation problems, moisture intrusion, electrical faults, and structural defects.

By providing a visual representation of temperature variations, thermography enhances the accuracy and efficiency of building surveys.

Unlike traditional survey methods that rely on physical inspections or invasive techniques, thermography allows surveyors to assess a building’s condition without causing disruption or damage. This non-destructive approach not only saves time but also reduces costs associated with repairs and remediation. Moreover, thermography can be performed from a safe distance, minimising risks to surveyors and ensuring their safety during the inspection process.

Commercial and Domestic Building Surveys using Thermography

Uncovering Hidden Issues: Common Problems Detected by Thermography in Building Surveys

- Insulation Problems: Inadequate insulation can lead to energy loss, discomfort, and increased utility bills. Thermography can identify areas of heat loss or cold air infiltration, enabling property owners to take corrective measures and improve energy efficiency.

- Moisture Intrusion: Water damage is a common issue in buildings and can lead to mold growth, structural deterioration, and health hazards. Thermography can detect moisture sources, such as leaks or condensation, by identifying temperature variations caused by evaporative cooling.

- Electrical Faults: Overloaded circuits, faulty wiring, and loose connections pose significant fire hazards. Thermography can identify hotspots in electrical systems, allowing for timely repairs and preventing potential disasters.

The Benefits of Thermography in Building Surveys: Saving Time, Money, and Ensuring Safety

- Time-Saving: Thermography enables surveyors to quickly scan large areas and identify potential issues in a fraction of the time required by traditional methods. This efficiency allows for more thorough inspections and faster reporting, saving both time and resources.

- Cost-Effective: By detecting hidden issues early on, thermography helps prevent costly repairs and damage. It allows property owners to address problems proactively, minimizing the risk of major structural or system failures that could result in significant financial burdens.

- Safety Assurance: Traditional survey methods often involve physical inspections that can be hazardous, especially in high-risk areas or inaccessible spaces. Thermography eliminates the need for invasive procedures, ensuring the safety of surveyors while providing accurate and reliable results.

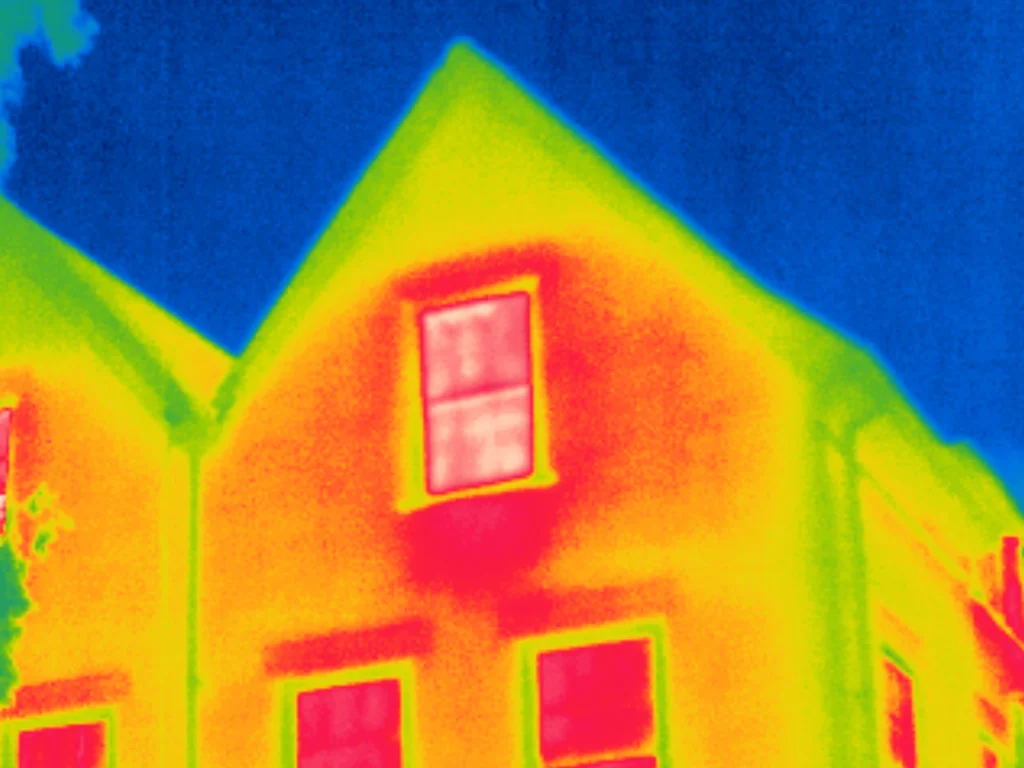

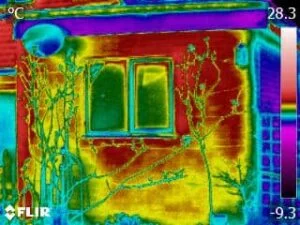

FLIR T530

Professional Commercial and Domestic Building Thermography using the latest technology in thermal imaging

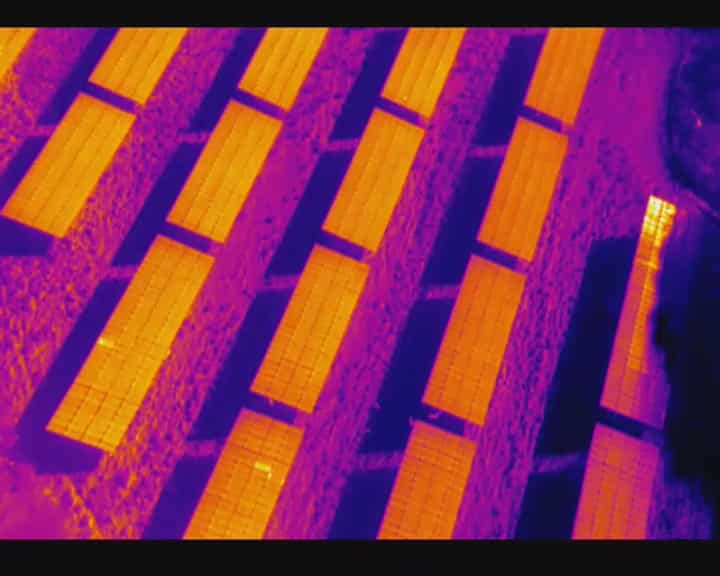

DJI XT2 and M300RTK Drone

Specialist Aerial Thermography using the latest advanced drones and thermal infrared camera payloads

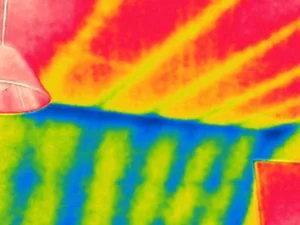

FLIR mr77 Moisture Detection

Moisture, dew point and condensation assessments are essential in determining thermal comfort

Thermography is a powerful tool that enhances building surveys by uncovering hidden issues that may otherwise go unnoticed. Its non-invasive nature, efficiency, and ability to detect a wide range of problems make it an invaluable asset in ensuring the safety, efficiency, and longevity of buildings. By investing in thermographic building surveys, property owners can save time, money, and ensure the well-being of their occupants.

Unlocking Building Secrets with Thermal Imaging Surveys

In the world of construction and property management, the quest for efficiency, comfort, and structural integrity is never-ending. Enter thermal imaging surveys, a cutting-edge technology that has revolutionized the way we assess buildings. In this comprehensive guide, we’ll explore the multifaceted role of thermal imaging in building surveys, dissecting key aspects like missing insulation, heat loss, moisture detection, dew point, condensation, and thermal bridging.

Uncovering Missing Insulation

One of the most prominent applications of thermal imaging in building surveys is the detection of missing insulation. Imagine being able to see through walls and roofs to identify areas where insulation is inadequate or completely absent. Thermal imaging makes this possible by capturing temperature variations. The significance of this cannot be overstated. In the UK, homes lose an estimated 25% of their heat through uninsulated roofs, costing homeowners hundreds of pounds annually in wasted energy and discomfort. By using thermal imaging, homeowners and property professionals can pinpoint insulation gaps, leading to substantial energy savings.

Battling the Chill: Heat Loss Detection

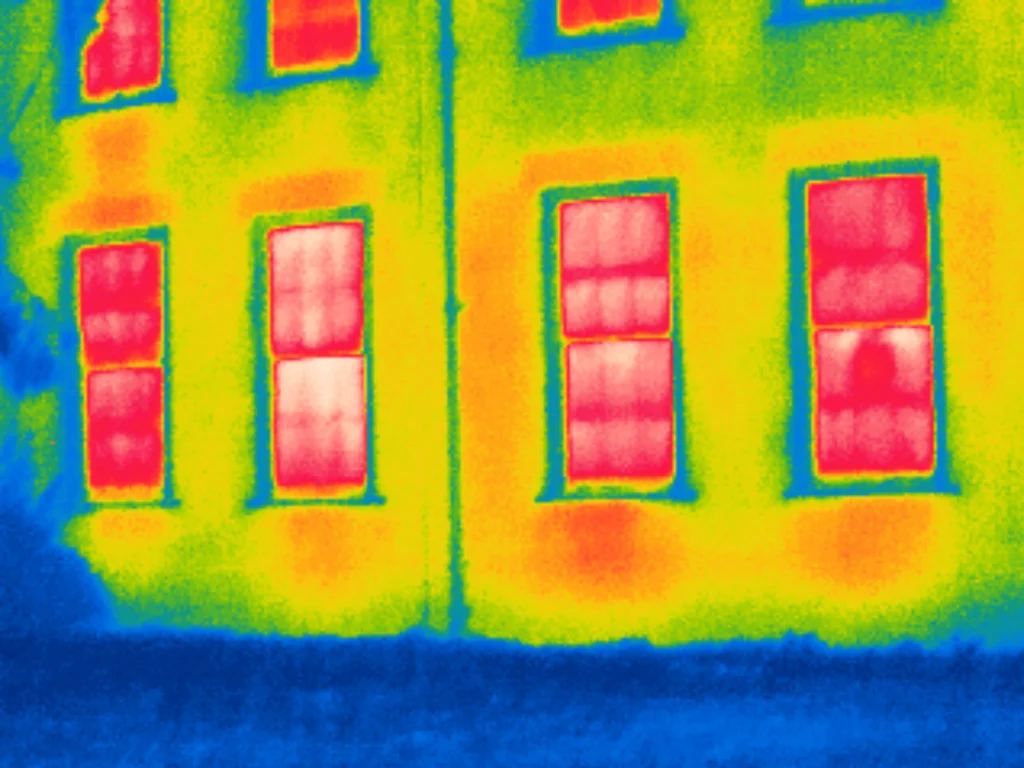

Heat loss is a pervasive issue, especially in older buildings. Thermal imaging surveys are a powerful tool for identifying where heat escapes or cold spots occur within a structure. These surveys provide a visual representation of temperature differences on building surfaces, enabling property owners to take targeted action. For instance, the insulation around windows and doors is often a weak point. Identifying these areas can result in significant energy savings and improved comfort for occupants. One study found that addressing heat loss through insulation upgrades can reduce heating bills by up to 20%.

The Battle Against Moisture: Detection and Prevention

Moisture infiltration can wreak havoc on a building’s structural integrity and occupants’ health. Thermal imaging surveys excel in moisture detection by revealing temperature anomalies that often indicate hidden leaks or damp areas. Addressing these issues promptly is crucial to prevent costly repairs and health-related problems. In the UK, where rainfall is a frequent occurrence, knowing how to detect and prevent moisture intrusion is vital. Thermal imaging helps identify roof leaks, plumbing issues, or damp spots on walls, allowing for timely intervention.

Understanding Dew Point and Conquering Condensation

Dew point and condensation can be particularly challenging in colder climates. Thermal imaging surveys provide the insights needed to understand and mitigate these issues. By identifying areas where dew point conditions are likely to occur, property professionals can select appropriate building materials and techniques to prevent condensation-related problems. For instance, in Scotland, where cold and damp conditions are common, understanding dew point is essential to maintain a building’s integrity and comfort levels.

Battling Energy Inefficiency: Thermal Bridging

Thermal bridging, or cold bridging, can significantly affect a building’s energy efficiency. Thermal imaging surveys play a pivotal role in identifying these areas where heat escapes or cold spots form. By addressing thermal bridging, property owners can enhance insulation and reduce heating costs. In the UK, where energy efficiency regulations are stringent, identifying and rectifying thermal bridging issues can lead to compliance and substantial energy savings.

Thermal imaging surveys have transformed the way we assess buildings, offering insights into insulation, heat loss, moisture issues, dew point, condensation, and thermal bridging. Armed with this technology, property professionals can enhance energy efficiency, protect investments, and create more comfortable living and working environments.

Building Surveys using Thermography

We are experienced and Certified Master Thermographer Level 3. We work boith from the air using specialist thermal drone technology as well as on the ground using traditional building thermal imaging techiques to inspect commericla and domestic properties.

Thermography is a non-destructive and non-invasive technology looking at the anomolies, faults and observations covering moisture, water ingress, insulation continuity, heat loss, air leakage, thermal bridging and insect infiltration.

Blog and Articles

Drone Media Imaging Qualifies as Category 2 level Thermographers We are delighted to announce that we are now qualified as Category 2 level thermographers! Hot on the heels of our recent announcement about obtaining enhanced operating safety case permissions from the Civil Aviation Authority (CAA), we can confirm that we have now completed certification to deliver specialist aerial thermal imaging services to industry standards recognised by the British [...]

As winter's chill recedes, the optimal period for building thermography is ending. This technology relies on temperature differences to detect energy inefficiencies. With spring's arrival, these disparities diminish, making it harder to identify problem areas. Act now to ensure your building's energy efficiency before the seasonal window closes.

Thermography, also known as thermal imaging, is a powerful tool that can be used to detect and analyze temperature variations in buildings. It has become increasingly popular in the field of energy efficiency as it allows for the identification of cold thermal air bridges and reverse chimney effects. By utilising thermography, building owners and energy efficiency professionals can take proactive measures to improve the energy performance and comfort of buildings.

Expert Infrared Inspections for Accurate Thermal Assessments

Need professional thermographic analysis for your project? Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.

related posts

The use of drones equipped with thermal imaging cameras has revolutionized fire safety measures in solid waste landfill sites. These drones can detect temperature variations and hotspots, allowing operators to identify areas at risk of combustion and take proactive measures to prevent fires. Additionally, thermal imaging technology can detect thermal emissions and chemical and physical parameters, providing valuable data for monitoring and managing landfill sites. This technology has already shown promising results, reducing the number of fire incidents in landfill sites and minimizing environmental impact and health risks. As the technology continues to advance, drone environmental thermal imaging is expected to become an indispensable tool in solid waste landfill site management.