Solar Panels and Thermal Imaging Inspections

The increasing drive towards meeting the nation’s energy needs through renewable energy sources such as solar and wind power has been big news in the construction and energy sectors for a long time now.

Solar panels are incorporated almost as standard onto new building housing and solar farms are no longer an uncommon sight in the English countryside. However, this increased usage also means that there is an increasing demand for maintenance to ensure that the panels are working at maximum capacity and so returning on their investment. Specialised maintenance teams exist to ensure exactly this but the sheer size of solar farms and inaccessibility of roof top installations can mean that preventative maintenance is not a cost effective use of their time. Fixing faults only after they have occurred can result in costly downtime and so to be able to pinpoint issues before they result in failure has to be the holy grail for maintenance firms.

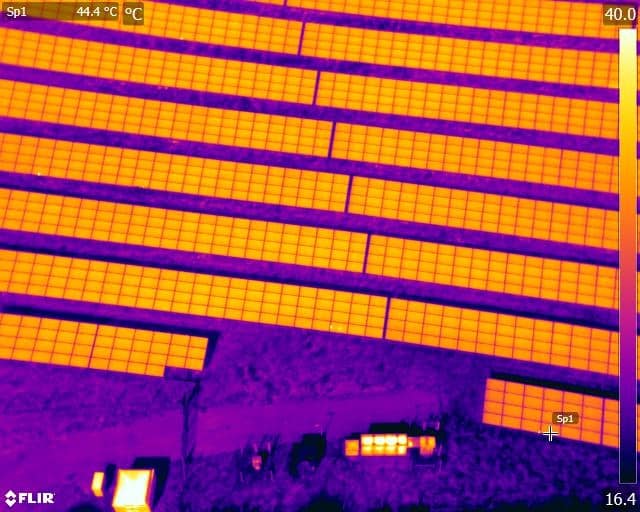

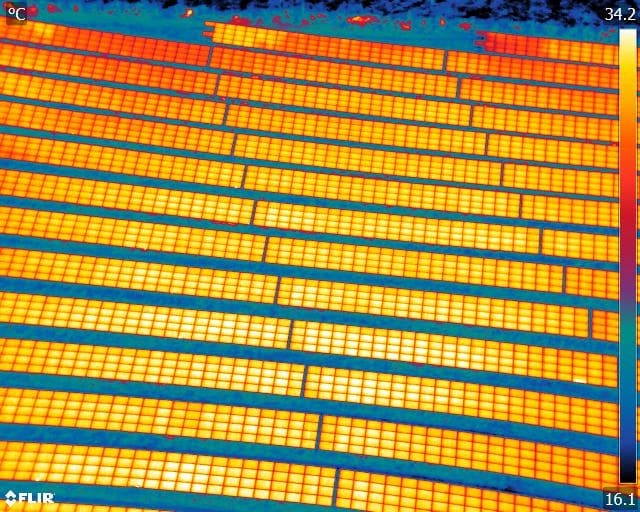

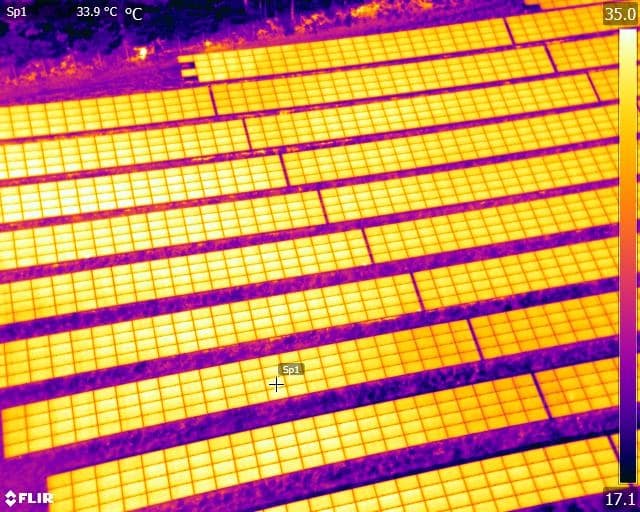

Thermal imaging cameras can offer the perfect solution, particularly when combined with the ability of drones to easily reach inaccessible rooftop installations and to cover large areas both quickly and efficiently.

Annual or biennial inspection flights can be easily achieved with flight patterns stored and reused making direct comparisons possible. As well as pinpointing problem areas to enable maintenance teams to be deployed with precision so their time is used to the maximum efficiency. Additionally, defective modules can be detected just after installation to ensure warranty services are applied for in time. All of this during normal panel operation, so no downtime costs are incurred during the inspection phase. Errors in photovoltaic modules tend to have quite high temperature differences of 10-20 degrees K making thermographic imaging an ideal tool to pinpoint them.

Drone Media Imaing is equipped with the FLIR ZenMuse XT radiometric 640 state of the art camera and a fleet of UAVs. The ZenMuse XT is fully integrated to the drone to offer live flight images at 640×512 resolution and, when combined with the FLIR toolbox, the ability to read the temperature from these images at almost pixel level as well as presenting them in a range of customisable colour palettes.

The Importance of Solar Panel Inspections in Spring

Spring and summer are peak months for solar energy production—ensure your panels are operating efficiently with a professional thermal imaging inspection. Compliance with IEC62446-3:2017 is essential for both commercial and domestic systems, helping to prevent faults, optimise performance, and maintain insurance coverage. Book your inspection today!

Facebook, Instagram and Threads Removal

Departing Facebook, Twitter, and Instagram to Uphold Ethical Principles In an era increasingly shaped by the influence of powerful social media platforms, Drone Media Imaging has made the principled decision to leave Facebook, [...]

In Thermography what is the difference between Quantitative vs Qualitative analysis

Quantitative and qualitative thermography are two essential methods in thermal imaging analysis. Quantitative thermography measures exact temperature values, while qualitative thermography focuses on pattern recognition. Both play a crucial role in building inspections, electrical fault detection, and industrial diagnostics. Understanding their differences helps professionals choose the right approach for accurate thermal assessments. Drone Media Imaging provides expert thermographic services, ensuring precise, reliable results. Contact us today for professional thermal imaging analysis.

Expert Infrared Inspections for Accurate Thermal Assessments

Need professional thermographic analysis for your project? Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.