The Drone Based Solar Farm Heat Hunt 🔍

Solar Farm Inspections using Thermal Imaging

Panel and string failures can not be seen by the naked eye

The world is moving towards renewable energy at a rapid pace, and solar farms are leading this transition.

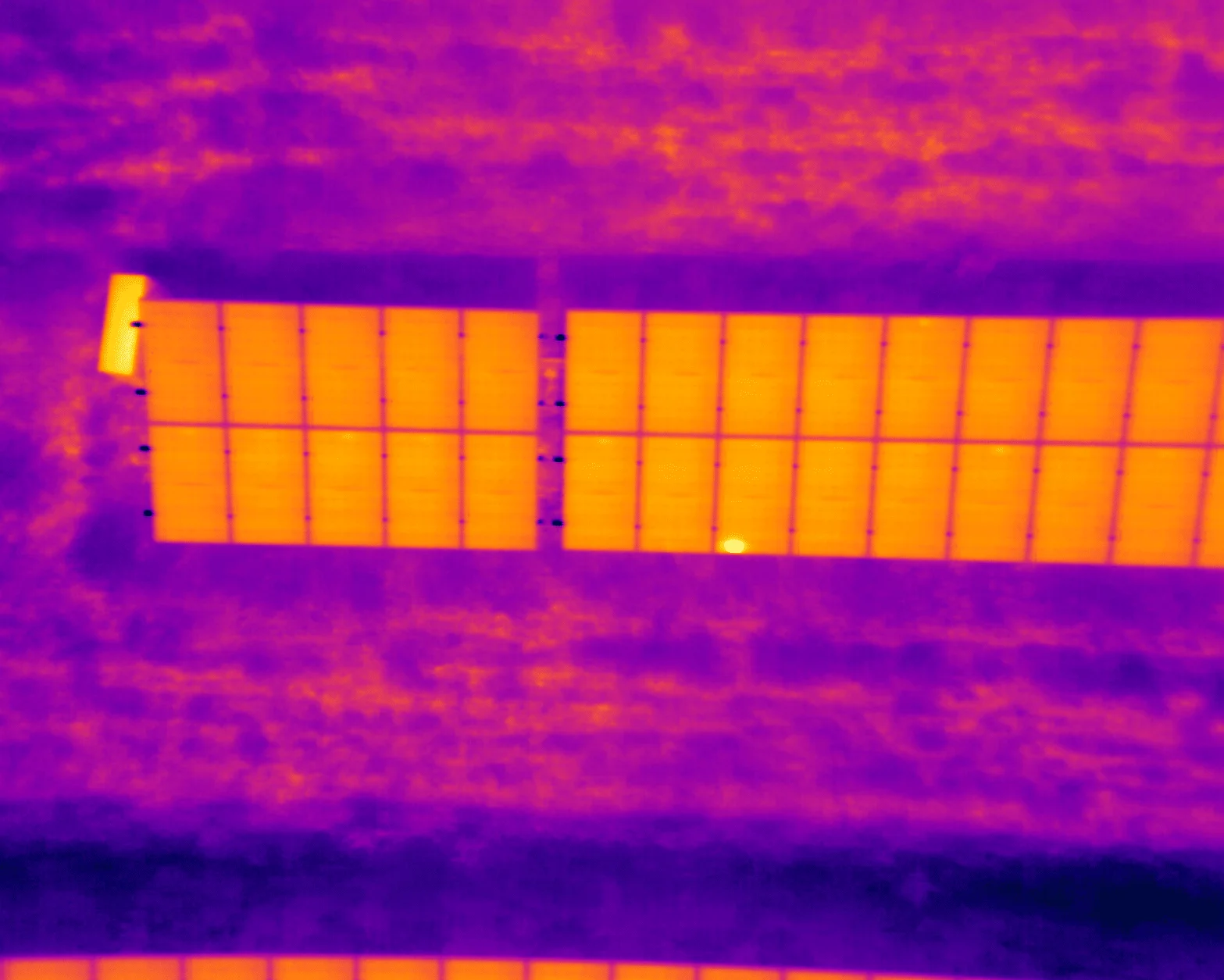

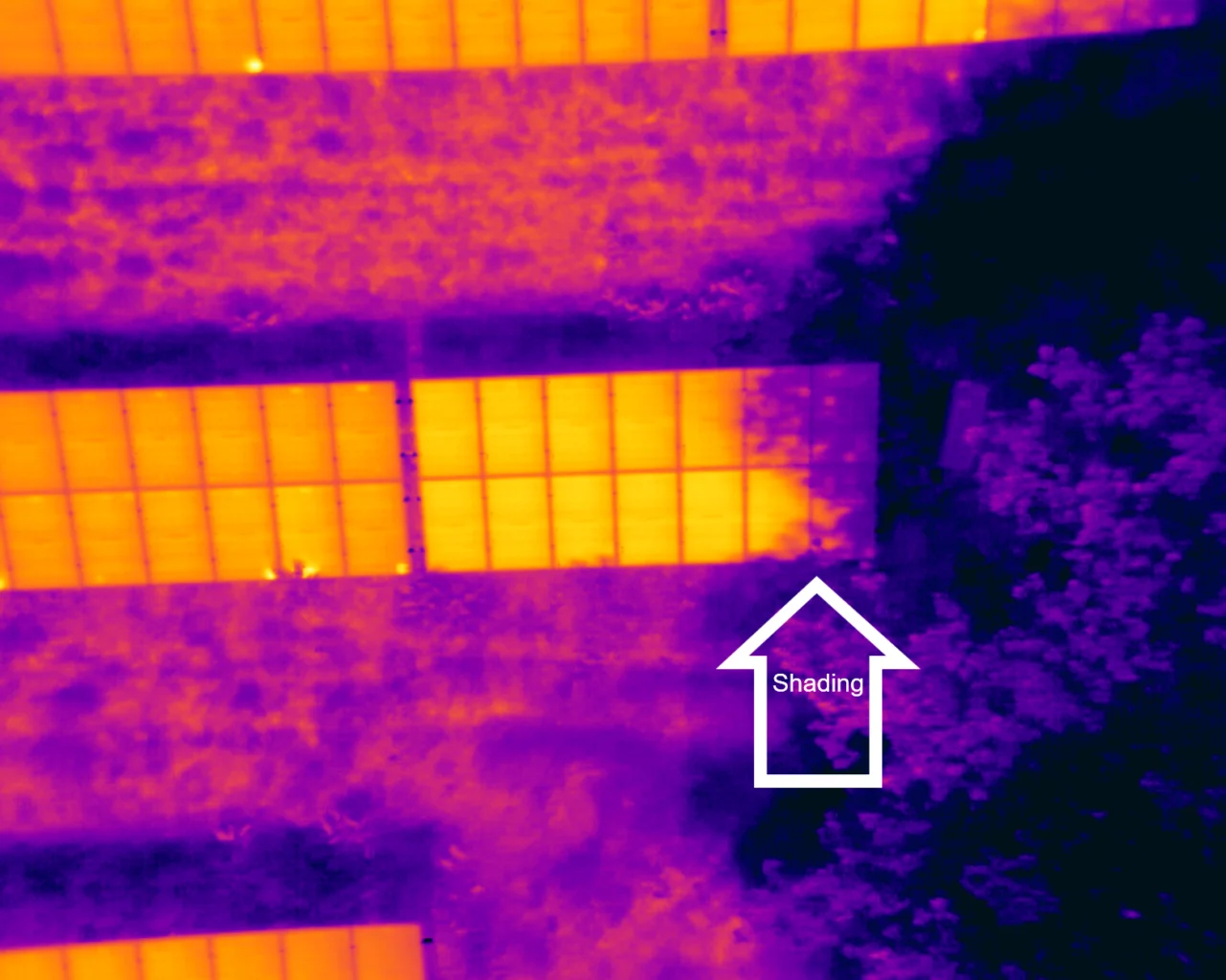

However, like any other technology, they come with their own set of challenges. One such challenge is identifying faults and anomalies such as ‘hotspots’ in the solar panels which can cause inefficiencies in energy production. Multiple hotspots, can lead to failing module panels and even whole strings.

However, using drone technolegy along with thermal camera payloads, detecting these issues is simple and straightforward! In this article, we will explore how drone thermal inspections of solar farms is the new normal.

Basking in the Sun: Drone-Powered Solar Farm Heat Hunts!

Drones have revolutionised the way we approach solar panel maintenance. With the help of thermal imaging cameras, drones can easily detect hotspots and module and diode failures in solar panels. These faults can occur due to a variety of reasons, such as debris or shading as wells as mechnical failure or a failure in manufacture, and can lead to significant energy losses collectively if not addressed in time. However, with drone-powered heat hunts, identifying and rectifying these hotspots issues has become a breeze.

Apart from improving energy production efficiency, drone-powered heat hunts also save time and money. Traditional methods of identifying hotspots anomalies involve shutting down the panels and conducting a visual and Voltage and Current testing and inspection. This not only requires significant time and labor but also results in production losses. With drones, heat hunts can be conducted quickly, safely and without any downtime, resulting in significant cost savings.

Solar Farm Temperature Analysis

By collecting data on the temperature of individual solar panels, drones can provide a comprehensive analysis of the farm’s overall performance. It can also determine imminent failures and developing faults by way of inspection comparisons over time. This analysis helps in identifying potential issues and allows for preventive maintenance, reducing the chances of downtime and production losses.

In addition, drone technology has also enabled solar farm operators to monitor and track changes in temperature over time. This data can be used to identify trends and patterns, allowing for better decision-making and optimisation of the solar farm’s performance. With the help of drones, solar farm operators can now have a bird’s eye view of their farms, making maintenance and management more efficient than ever before.

In conclusion, drone-powered heat hunts have become a game-changer for solar farm reactive and preventative maintenance. With their ability to quickly detect hotspots, drones have significantly improved the efficiency and performance of solar farms. As the world moves towards clean and renewable energy, drones will undoubtedly play a crucial role in ensuring the sustainability and profitability of solar farms.

IEC Solar Farm Inspection Services

We are certified thermographers, experienced in solar farm inspections to IEC standards. We can complete both the structured and compliant data capture, through to the formal inspection report.

As approved drone pilots we work throughout the UK to provide both aerial and ground based thermography services. Fully insured and certified by the CAA with enhanced permissions for day and night time flights

Expert Infrared Inspections for Accurate Thermal Assessments

Need professional thermographic analysis for your project? Our certified experts use the latest infrared technology to deliver precise results. Contact Drone Media Imaging today for expert thermal imaging services.

related posts

Discover why spring is the perfect time for solar panel inspections and how it can maximize your energy efficiency and savings.